Where is the professionalism of Professional Tool Cabinet Series mainly reflected?

The professionalism of a Professional Tool Cabinet Series is mainly reflected in several key aspects, which collectively contribute to the quality and functionality of these cabinets. Here are the main areas where professionalism is evident in Professional Tool Cabinet Series:

Build Quality and Durability:

Professional-grade tool cabinets are constructed with robust and durable materials, such as heavy-gauge steel, aluminum, or high-quality wood. The choice of materials and manufacturing processes ensures the cabinets can withstand the demands of professional use and the rigors of various work environments.

Precise Engineering:

Professional tool cabinets are typically engineered with precision. The design and construction of these cabinets ensure precise dimensions, square corners, and tight tolerances. This attention to detail results in seamless operation and long-lasting performance.

High Load Capacity:

The ability to support heavy tools and equipment is a hallmark of professional tool cabinets. These cabinets are built to handle substantial weight without warping, bending, or showing signs of wear, making them reliable for storing and organizing a broad range of tools.

Security Features:

Professional tool cabinets often feature advanced security measures, such as secure locking mechanisms, tamper-resistant designs, and options for locking individual drawers. These features protect valuable tools and prevent unauthorized access.

Organizational Efficiency:

Professional-grade cabinets are designed for maximum organizational efficiency. They offer adjustable shelves, drawers, dividers, and compartments, allowing users to customize the interior layout to suit their specific tools and equipment.

Smooth Operation:

Professional tool cabinets are engineered for smooth and precise operation. High-quality ball-bearing slides and drawer glides ensure that drawers open and close effortlessly. This smooth operation enhances workflow efficiency.

Powder-Coated Finish:

The cabinets are often finished with a durable powder-coated finish. This finish not only adds a professional and clean appearance but also provides protection against corrosion, chipping, and UV damage.

Customization Options:

Professional tool cabinets often offer a range of customization options. Users can add accessories like hooks, bins, pegboards, or workbench attachments to optimize organization and storage efficiency for their specific work needs.

Tool Identification and Management:

Some professional cabinets come with features like tool identification systems, allowing for quick and efficient tool management. These systems help users locate and account for tools with ease.

Diverse Configurations:

Professional Tool Cabinet Series offers diverse configurations, including wall-mounted, floor-standing, and modular options. This versatility allows professionals to select the configuration that best suits their workspace and storage requirements.

Ergonomics and Accessibility:

Professional cabinets prioritize ergonomic design, ensuring that tools are accessible with minimal effort. This feature minimizes strain and enhances work efficiency for professionals using the cabinets daily.

Warranty and Customer Support:

Many professional-grade tool cabinets come with extended warranties and comprehensive customer support. This reflects the manufacturer's commitment to the product's durability and the satisfaction of professional users.

Safety Features:

Professional cabinets may incorporate safety features such as secure locking mechanisms for hazardous or valuable tools, anti-tip designs to prevent accidental cabinet tip-overs, and fire-resistant options.

In summary, professionalism in a Professional Tool Cabinet Series is demonstrated through its exceptional build quality, engineering precision, high load capacity, security features, organizational efficiency, smooth operation, customization options, diverse configurations, and its overall suitability for demanding professional applications. These cabinets are designed to meet the specific needs and high standards of professionals who rely on them to efficiently and securely store and manage their tools and equipment.

How to test whether the Professional Tool Cabinet Series error meets the standards?

To test whether a

Professional Tool Cabinet Series meets the standards and ensure its quality and functionality, you can perform a series of tests and inspections. These tests can help identify any errors or deviations from the expected standards. Here is a step-by-step process to evaluate the cabinet:

Visual Inspection:

Begin with a visual inspection of the cabinet. Check for any visible defects, damage, or irregularities in the cabinet's construction, finish, and components. Look for scratches, dents, or misalignments.

Measurements and Dimensions:

Verify that the cabinet's measurements and dimensions match the specifications provided by the manufacturer. Use a tape measure or calipers to check the width, height, depth, and other critical dimensions.

Load Capacity Test:

Test the load capacity of the cabinet by placing weights or tools inside it. Ensure that it can comfortably support the specified weight limit without sagging, bending, or showing signs of structural weakness.

Smooth Operation Test:

Open and close all drawers and doors to assess their smoothness of operation. They should glide or swing open and closed smoothly without binding, sticking, or excessive friction. Pay attention to the operation of any locking mechanisms.

Lock and Security Test:

If the cabinet has locking mechanisms, test their functionality. Ensure that they securely lock and unlock as intended, and that keys or codes work without issues.

Drawer Slide and Glide Test:

Test the drawer slides and glides by fully extending and retracting the drawers. They should extend smoothly and evenly and remain securely closed when pushed in.

Durability and Material Test:

Assess the durability of the cabinet material by performing a scratch test, impact resistance test, and chemical resistance test (if applicable). The cabinet should withstand everyday wear and tear.

Alignment and Squareness Test:

Check for alignment and squareness of the cabinet by using a framing square. Corners and edges should be perfectly square and not misaligned.

Safety and Stability Test:

Conduct a stability test to ensure the cabinet is not prone to tipping over when drawers or doors are open. A well-designed cabinet should be stable and safe to use.

Accessories and Customization Test:

If the cabinet comes with accessories or customization options, test their compatibility and functionality. Ensure that they can be easily installed or integrated into the cabinet.

Warranty and Documentation Review:

Review the manufacturer's warranty, instructions, and documentation for any specific testing requirements or recommendations. Follow the manufacturer's guidelines for product evaluation.

User Experience Feedback:

Seek feedback from users who have experience with the same or similar cabinet models. User reviews and experiences can provide valuable insights into the cabinet's performance and any potential issues.

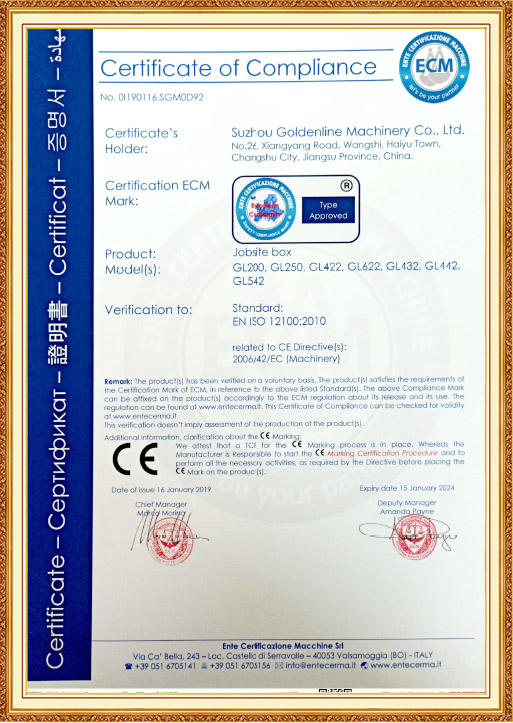

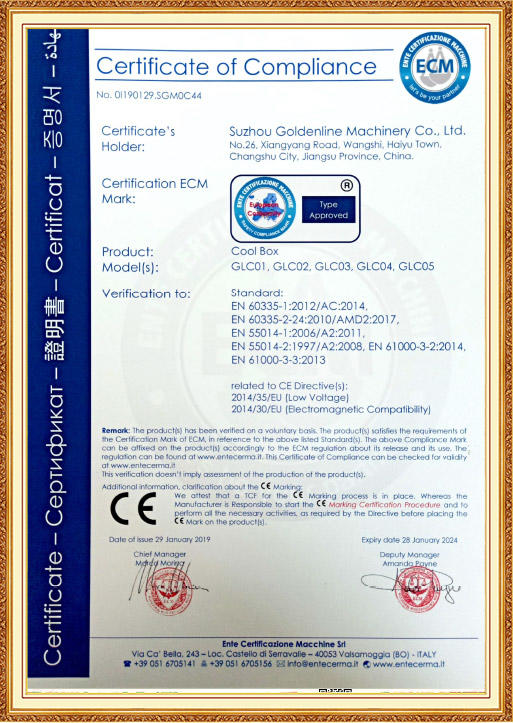

Safety and Compliance Standards:

Ensure that the cabinet meets relevant safety and compliance standards and regulations. These standards can vary by region, so consult local authorities or regulatory bodies if necessary.

Operational Field Test:

If possible, place the cabinet in its intended operational environment and use it as you would in your daily work. This can help identify any operational challenges or errors that may not be evident during initial inspection.

Document Test Results:

Document the results of each test, noting any deviations from standards or errors observed during the evaluation.